The Chinese automotive air conditioner filter industry has witnessed consistent market expansion in recent years, driven by multiple factors. Rising vehicle ownership, heightened consumer health awareness, and supportive policies are fueling growth, especially with the rapid development of the new energy vehicle market. As consumers increasingly prioritize in – car air quality, the demand for high – efficiency filters is soaring. The market size is projected to reach 6.1 billion RMB by 2025.

Diversified Product Portfolio

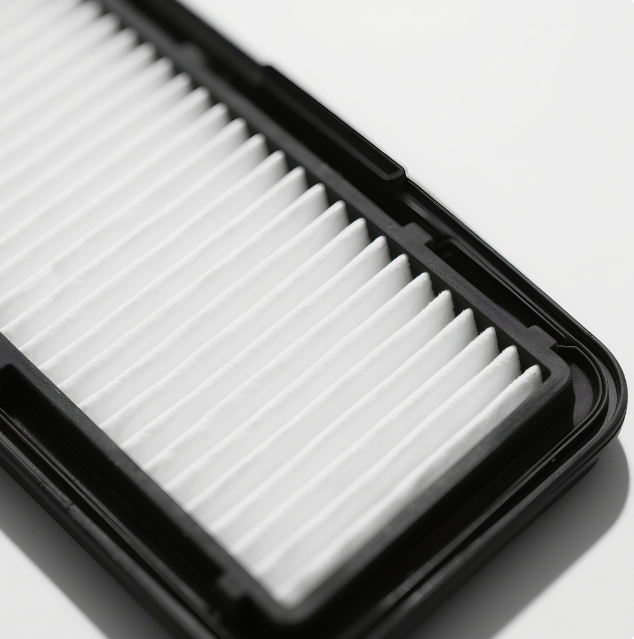

The market offers a range of products, including basic filters, activated carbon filters, antibacterial filters, and HEPA filters. Among them, high – efficiency filters are gaining traction due to their ability to meet consumers’ needs for cleaner in – car air. In terms of market structure, low – end products dominate, accounting for 65.38% of the market share.

Key player: Air Filtration Non Woven Materials

Filter Nonwoven plays a pivotal role in automotive air conditioner filters, serving as the core material for contaminant removal. Its unique structure—composed of randomly oriented fibers—creates a dense network that efficiently traps particles, allergens, and harmful gases. Nonwovens offer superior filtration efficiency, flexibility, and cost – effectiveness. For instance, JOFO filtration’s Air Filtration Non Woven Materials, with their ultra – fine fibers, can capture even submicron particles, making them critical for HEPA filters. Air Filtration Material-Meltblown nonwoven fabric is widely used for air purifier, as a sub-efficient and efficient air filter element, and for coarse and medium-efficiency air filtration with high flow rate. JOFO filtration is committed to research, develop and manufacture the high-efficiency air purification materials, provide stable and high-performance filter materials for the global air purification field.

Future Outlook: High – tech and Sustainable Development

The industry is heading towards efficiency, intelligence, and environmental friendliness. Advanced filtering materials and antibacterial technologies will enhance air purification. Smart sensors will enable automatic air quality monitoring and adjustment, while eco – friendly, recyclable materials will reduce environmental impact. Low – resistance and long – lasting designs, especially suitable for new energy vehicles, will meet evolving market demands, driving the industry’s high – end and sustainable transformation.

Post time: May-20-2025